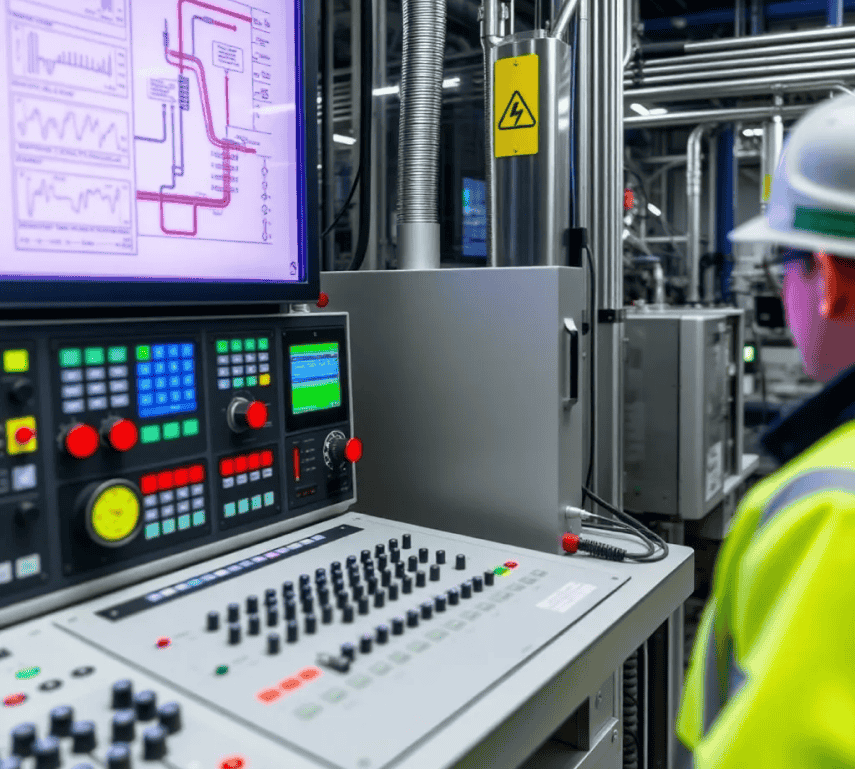

Control panel manufactured by Kveetech in Evaporation & Distillation Processes

Our Control Panel are the advanced automation system designed for monitoring and controlling various parameters within evaporation and distillation processes. It allows operators to maintain optimal conditions, ensuring product quality and operational efficiency. By integrating cutting-edge technology

This comprehensive guide covers everything from understanding the basic functions of our panel to advanced troubleshooting techniques for common issues that may arise By using our expertise in control panel to achieve optimal results in their evaporation and distillation operations, making it an invaluable tool for anyone looking to enhance their chemical processing capabilities. This advanced control system offers precise control over parameters such as speed, temperature, and pressure, ensuring that the mixing process is carried out efficiently and accurately With its user-friendly interface and customizable settings, operators can easily adjust and monitor the mixing process to achieve desired results. Additionally, the Kveetech control panel provides real-time data monitoring and analysis, allowing for effective troubleshooting and optimization of the mixing operation. Overall, this cutting-edge technology enhances productivity, quality control, and safety in mixing applications, making it an indispensable tool for professionals in industries such as pharmaceuticals, food processing, and chemical manufacturing.

Our panels are widely used and known for drying applications when combined with PLC and SCADA technology. These control panels provide advanced monitoring and control capabilities allowing for precise regulation of temperature, humidity, and airflow to optimize the drying process. The integration of PLC (Programmable Logic Controller) enables automated control of the various components involved in the drying operation, ensuring consistent and accurate performance. Additionally, SCADA (Supervisory Control and Data Acquisition) systems offer real-time data monitoring and analysis, allowing operators to make informed decisions to improve efficiency and productivity.

Our control panels integrated with PLC and SCADA technology provide a sophisticated solution for optimizing drying processes in various industries such as food processing, pharmaceuticals, textiles, and more.

In the realm of drying applications, Programmable Logic Controllers (PLCs) play a crucial role in ensuring efficient and precise control over various processes. Our PLC panels are specifically designed to handle complex automation tasks in industrial settings, making them indispensable for optimizing drying operations By using PLCs, operators can easily program and monitor parameters such as temperature, humidity, airflow, and timing with high accuracy and reliability. This enables enhanced process consistency, reduced energy consumption, and improved product quality by eliminating human errors and inconsistencies. Our well designed PLCs allow for seamless integration with other systems such as sensors and actuators, providing a comprehensive solution for controlling the entire drying process. Overall, PLCs in drying applications offer unparalleled capabilities for achieving optimal performance and productivity while maintaining strict quality standards within industrial environments.

Our advanced control system offers precise control over parameters such as speed, temperature, and pressure, ensuring that the mixing process is carried out efficiently and accurately With its user-friendly interface and customizable settings, operators can easily adjust and monitor the mixing process to achieve desired results. Additionally, the Kveetech control panel provides real-time data monitoring and analysis, allowing for effective troubleshooting and optimization of the mixing operation. Overall, our panels help the mixing industry to enhances productivity, quality control, and safety in mixing applications. Making it an indispensable tool for professionals in industries such as pharmaceuticals, food processing, and chemical manufacturing.

Our panel are providing the advanced industrial control solutions in PLC panel tailored for mixing applications. This control panel is designed to efficiently regulate and automate the complex processes involved in blending various materials or substances. Our PLC control panel ensures accurate measurements, consistent mixing ratios, and optimal production rates. The user-friendly interface allows operators to easily monitor and adjust parameters such as flow rates, temperatures, and mixing speeds. .

Our panels are equipped with sensors mechanism that provide real-time data on the mixing process, allowing for quick adjustments and corrections to minimize waste and ensure consistent product quality Our robust design makes it easy to use in all techical aspects . Overall, Kveetech control panel offers precise control and monitoring capabilities that are essential for achieving superior results in complex mixing applications.

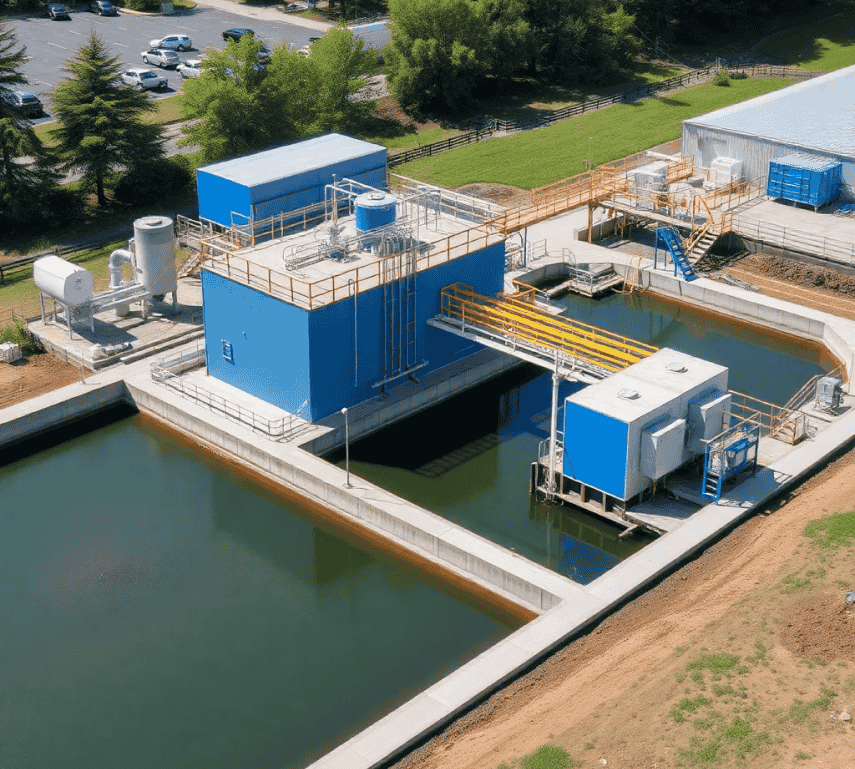

In the water management industry, regulating and monitoring processes in sewage treatment plants (STP), wastewater treatment plants (WWTP), and effluent treatment plants (ETP). Our control panels are equipped with advanced technologies to efficiently manage the flow of water, chemicals, and other components within these facilities. our control panels include Supervisory Control And Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLC), Human Machine Interface (HMI) panels, Distributed Control Systems (DCS), and Remote Terminal Units (RTU) Each of our control panels serves a specific function in controlling various operations such as pumping, filtration, disinfection, and sludge removal process .Our control panels in STP/WWTP/ETP applications, various industries and companies can ensure optimal performance, improve operational efficiency, and maintain compliance with regulations governing water treatment processes

In the field of sewage treatment plants (STP), wastewater treatment plants (WWTP), and effluent treatment plants (ETP), Our control panels used in these applications include PLC-based control panels, SCADA systems, and automation control panels. Our control panels are designed to automate and regulate processes such as filtration, disinfection, sludge handling, and more. PLC-based control panels utilize programmable logic controllers to facilitate efficient operation and customization of the plant’s functions. SCADA systems enable remote monitoring and control of plant operations through data acquisition and visualization. Kveetech Automation control panels integrate various sensors, actuators, and controllers to streamline processes within the plant. Overall, these advanced control panel technologies enhance operational efficiency, accuracy, and safety in STP/WWTP/ETP applications by providing real-time monitoring, data analysis, and system optimization capabilities in any plant or industry

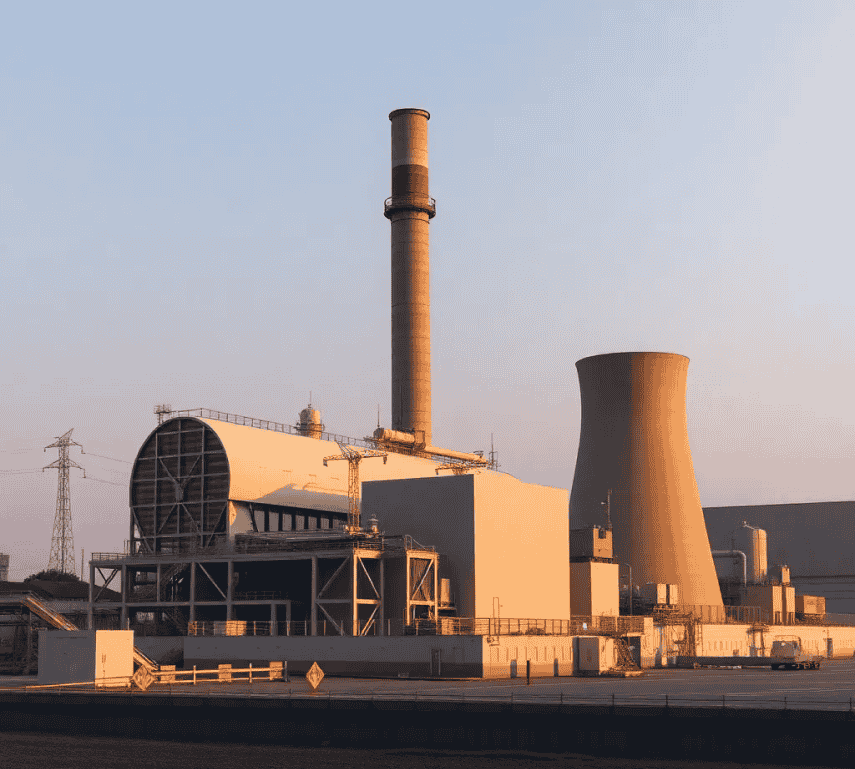

Our control panels help to managing and monitoring various aspects of power generation systems, ensuring efficient operation and optimal output. Kveetech control panels reflect their functionality and purpose within the power generation process. Examples of such names include the Generator Control Module (GCM), Turbine Monitoring System (TMS), and Power Distribution Unit (PDU). Each of these control panels is designed to precise control over critical operations, thereby enhancing overall system efficiency and safety. With Kveetech control panels at power generation facilities can achieve seamless operation and maximum productivity.

In the context of power generation plants, Our control panels are used in such facilities include Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, Human-Machine Interface (HMI), Programmable Logic Controllers (PLC), and Remote Terminal Units (RTU). DCS is a centralized system that integrates multiple control units to provide real-time data monitoring and control capabilities. SCADA systems are designed for remote monitoring and controlling of different plant components through graphical interfaces. HMIs provide operators with user-friendly displays for interacting with the control system. PLCs are programmable devices used to automate specific tasks within the plant, while RTUs collect data from remote terminals and transmit it to the central control unit. Each of these control panels serves a unique purpose, facilitating efficient operation and maintenance of power generation plants.

In the water management industry, regulating and monitoring processes in sewage treatment plants (STP), wastewater treatment plants (WWTP), and effluent treatment plants (ETP). These control panels are equipped with advanced technologies to efficiently manage the flow of water, chemicals, and other components within these facilities. our control panels include Supervisory Control And Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLC), Human Machine Interface (HMI) panels, Distributed Control Systems (DCS), and Remote Terminal Units (RTU) Each of these control panels serves a specific function in controlling various operations such as pumping, filtration, disinfection, and sludge removal. By utilizing kveetech sophisticated control panels in STP/WWTP/ETP applications, professionals can ensure optimal performance, improve operational efficiency, and maintain compliance with regulations governing water treatment processes

Control panels are an essential component in HVAC systems, serving as the central nervous system that regulates the operation and performance of heating, ventilation, and air conditioning equipment. Some commonly used control panel of Kveetech are within the HVAC industry include programmable logic controllers (PLCs), building automation systems (BAS), direct digital controls (DDC), and smart thermostats. PLCs are advanced digital computers that can automate complex tasks such as regulating temperature, humidity, and airflow in commercial buildings. DDC systems utilize sensors and actuators to continuously adjust HVAC settings based on real-time data, providing precise environmental control. Smart thermostats offer remote access and intelligence features, allowing users to personalize comfort settings while conserving energy.

Kveetech is a manufacturer of control panels that have gained recognition in the HVAC industry for their precision and reliability. Their control panels are designed with advanced technology to regulate and monitor the various components of HVAC systems, such as air conditioning units, heating systems, and ventilation equipment. , Kveetech control panels provide HVAC professionals with the tools they need to effectively manage and maintain complex heating and cooling systems. Overall, Kveetech’s commitment to quality and innovation has established them as a trusted provider of control solutions in the HVAC industry.

Kveetech Enterprises is engaged in manufacturing and supplying of wide range of Industrial Control Panels & Service Providers.